自制基于Arduino的剥线器

发布时间: 2025-06-10 17:37:41 |  0

0 0

0 0

0 0

0

0

0Arduino

Arduino

线材切割机

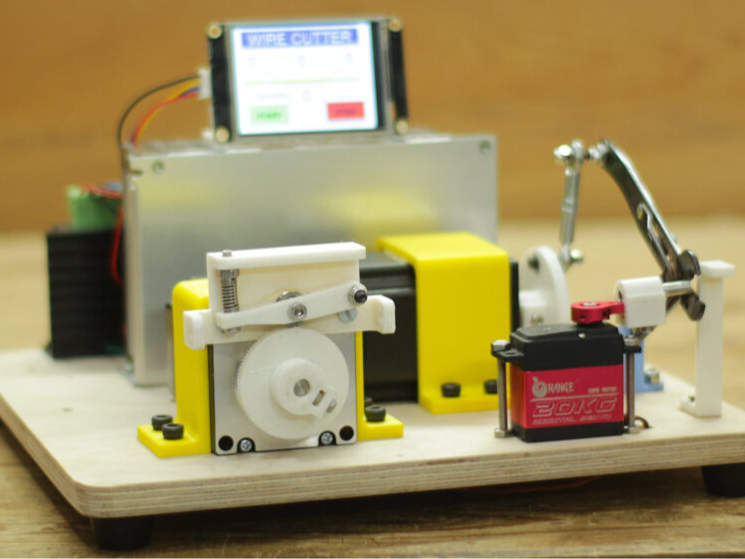

在这篇文章中,我使用Nema 23步进电机构建了一台基于Arduino的剥线器

这台机器能够根据小型人机界面提供的数据自动切割和剥线。

准备工作:

材料:

材料名称

数量

备注

Arduino Nano

1

\

Nema 23 步进电机

2

\

TB6600 步进电机驱动

2

\

剥线钳

1

\

12V 10A 120W 开关电源

1

\

2.8 英寸 电阻式触摸显示屏

1

\

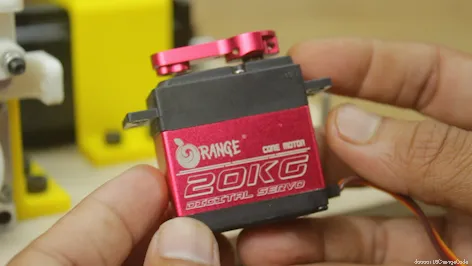

舵机

1

20KG

1

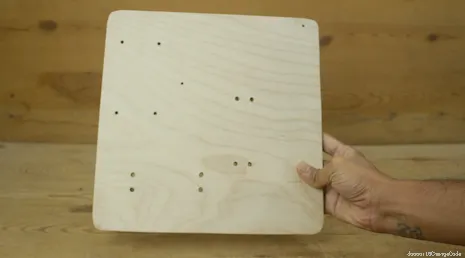

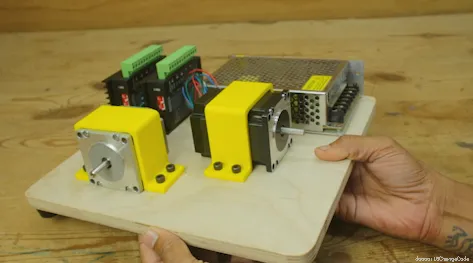

底座制作

首先,我使用12毫米厚的木板准备机器的底座,这块木板的尺寸是125 x 125毫米。

我用曲线锯机切割胶合板,并借助台式砂光机打磨边缘使其光滑。

并在木制底座上钻了一些孔,以便将组件安装在上面。

此外,为了更好的抓地力,我在木制底座的底部放置了四个橡胶脚。

2

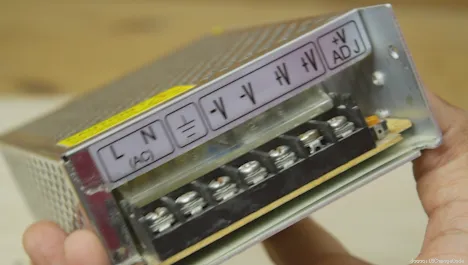

供电

我使用这个12V 10A 120W 开关电源步进电机供电

3

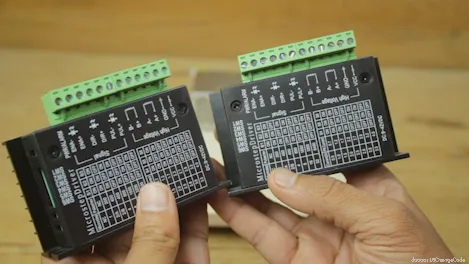

电机驱动

这是用于运行 nema 23 步进电机的 TB6600 步进电机驱动器。

TB6600 系列Arduino 步进电机驱动器是一款易于使用的专业步进电机驱动器,可以控制两相步进电机。

4

组件固定

把所有组件安装在木制底座上

5

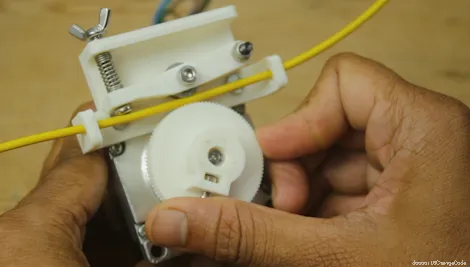

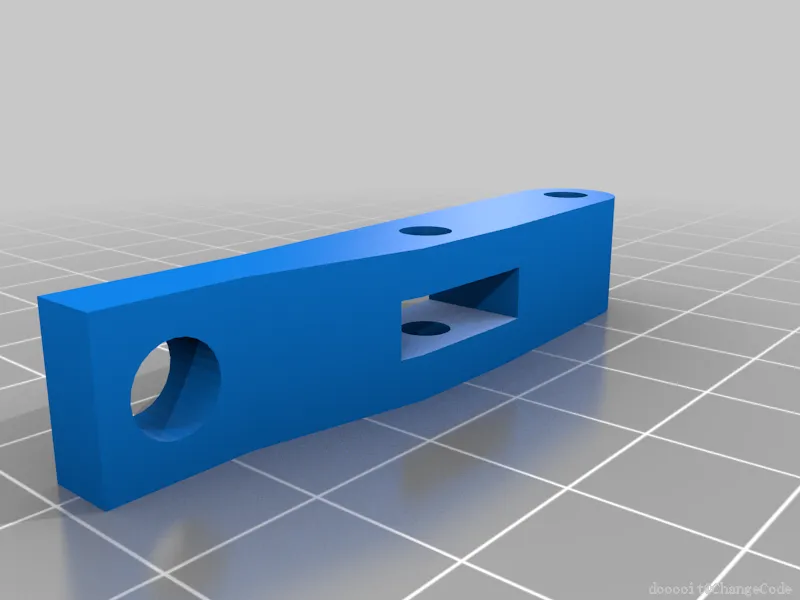

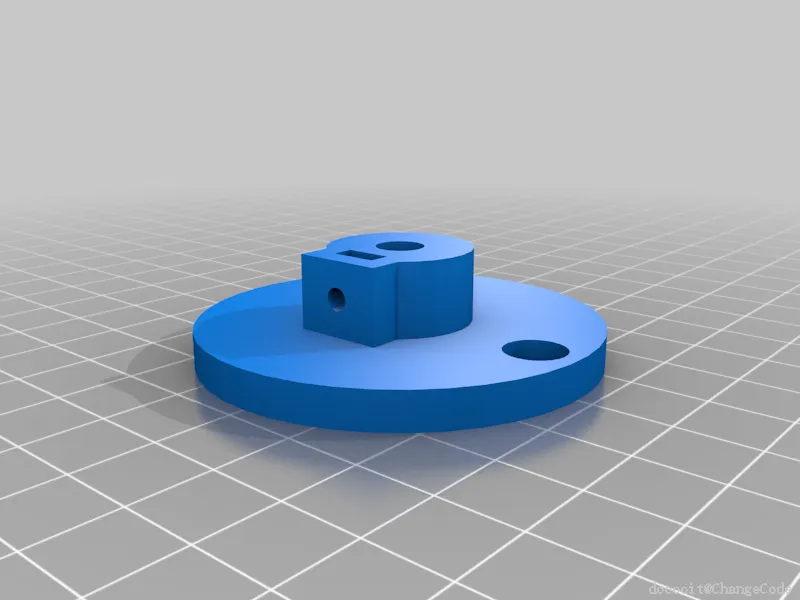

送丝机

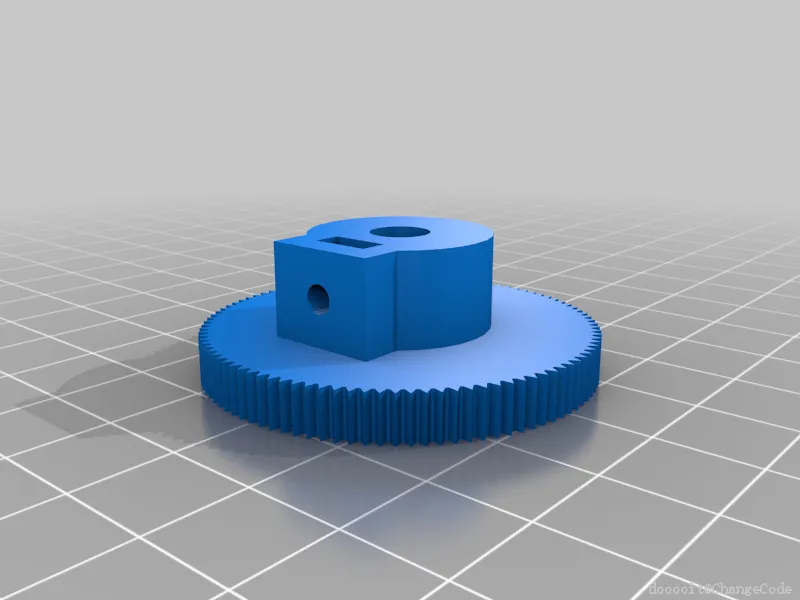

使用3D 打印的部件制作了这个送丝机机构

它在Nema 23步进电机的轴上安装了一个较大的夹紧轮。

并通过弹簧的帮助,在这个轮子上压入了一个小的开槽轴承。

电线通过这两个轮子之间的间隙进行供给。

6

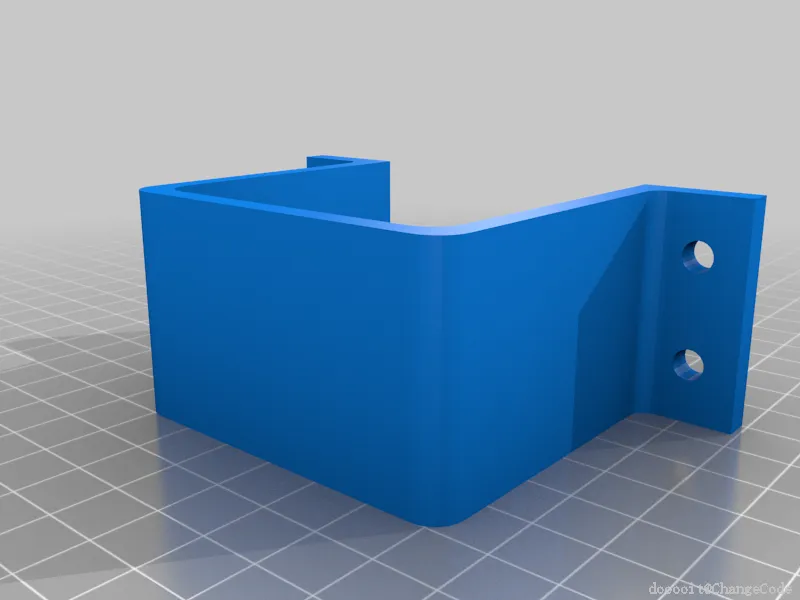

舵机引导电线

使用高扭矩伺服电机引导电线穿过剪线钳。

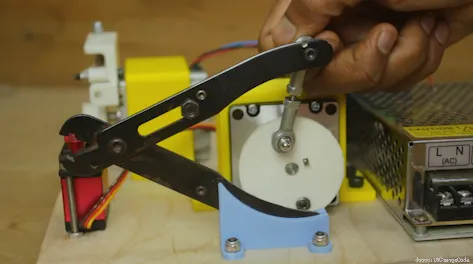

7

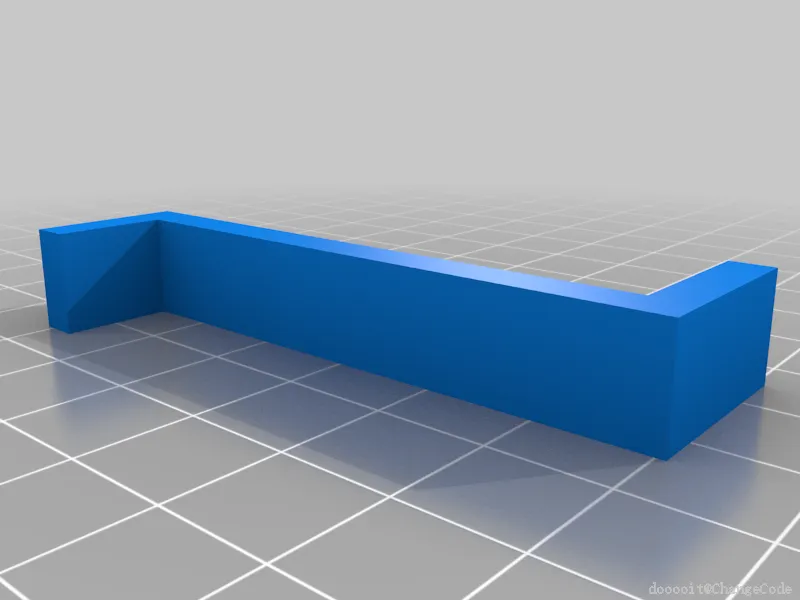

连杆连接

我使用连杆连接了切线器的末端和步进电机。

我使用了两个带有中间螺丝的关节,因为它的长度可以根据电线的粗细进行增加或减少。

8

组装成品

最后,机器组装完成了,现在是时候将代码上传到Arduino和HMI了。

9

Arduino代码

#include <Stepper.h>

#include <Arduino.h>

#include "BasicStepperDriver.h"

#include "MultiDriver.h"

#include "SyncDriver.h"

#include <SoftwareSerial.h>

#include <Servo.h>

//SoftwareSerial mySerial(2, 3); // RX, TX

Servo myservo;

int A = 0;

int B = 0;

int state = 0;

String message;

int QTY, numMessages, endBytes;

byte inByte;

int flag = 0;

int C=0;

float D=0;

int E=0;

int Start = 22;

int End = 31;

#define MOTOR_STEPS 200

#define DIR_X 7

#define STEP_X 4

#define DIR_Y 6

#define STEP_Y 3

#define MICROSTEPS 16

#define MOTOR_X_RPM 50

#define MOTOR_Y_RPM 200

BasicStepperDriver stepperX(MOTOR_STEPS, DIR_X, STEP_X);

BasicStepperDriver stepperY(MOTOR_STEPS, DIR_Y, STEP_Y);

SyncDriver controller(stepperX, stepperY);

void setup()

{

numMessages, endBytes = 0;

myservo.attach(10);

Serial.begin(9600);

//mySerial.begin(9600);

stepperX.begin(MOTOR_X_RPM, MICROSTEPS);

stepperY.begin(MOTOR_Y_RPM, MICROSTEPS);

myservo.write(Start);

delay(2000);

}

void loop()

{

data();

if (A > 0 && B > 0 && C > 0) {

delay(2000);

for (int i = 0; i < C; i++){

controller.move(A*25, 0 );

delay(500);

controller.rotate(0, 360 );

delay(500);

controller.move(B*25, 0 );

delay(500);

controller.rotate(0, 360 );

delay(500);

controller.move(A*25, 0 );

delay(500);

myservo.write(End);

delay(500);

controller.rotate(0, 360 );

delay(500);

myservo.write(Start);

delay(500);

Serial.print(i);

}

A=0;

B=0;

C=0;

}

}

void data() {

if (state == 0) {

if (numMessages == 1) { //Did we receive the anticipated number of messages? In this case we only want to receive 1 message.

A = QTY;

Serial.println(A);//See what the important message is that the Arduino receives from the Nextion

numMessages = 0; //Now that the entire set of data is received, reset the number of messages received

state = 1;

}

}

if (state == 1) {

if (numMessages == 1) { //Did we receive the anticipated number of messages? In this case we only want to receive 1 message.

B = QTY;

Serial.println(B);//See what the important message is that the Arduino receives from the Nextion

numMessages = 0; //Now that the entire set of data is received, reset the number of messages received

state = 2;

}

}

if (state == 2) {

if (numMessages == 1) { //Did we receive the anticipated number of messages? In this case we only want to receive 1 message.

C = QTY;

Serial.println(C);//See what the important message is that the Arduino receives from the Nextion

numMessages = 0; //Now that the entire set of data is received, reset the number of messages received

state = 0;

}

}

if (Serial.available()) { //Is data coming through the serial from the Nextion?

inByte = Serial.read();

// Serial.println(inByte); //See the data as it comes in

if (inByte > 47 && inByte < 58) { //Is it data that we want to use?

message.concat(char(inByte)); //Cast the decimal number to a character and add it to the message

}

else if (inByte == 255) { //Is it an end byte?

endBytes = endBytes + 1; //If so, count it as an end byte.

}

if (inByte == 255 && endBytes == 3) { //Is it the 3rd (aka last) end byte?

QTY = message.toInt(); //Because we have now received the whole message, we can save it in a variable.

message = ""; //We received the whole message, so now we can clear the variable to avoid getting mixed messages.

endBytes = 0; //We received the whole message, we need to clear the variable so that we can identify the next message's end

numMessages = numMessages + 1; //We received the whole message, therefore we increment the number of messages received.

//Now lets test if it worked by playing around with the variable.

}

}

}

10

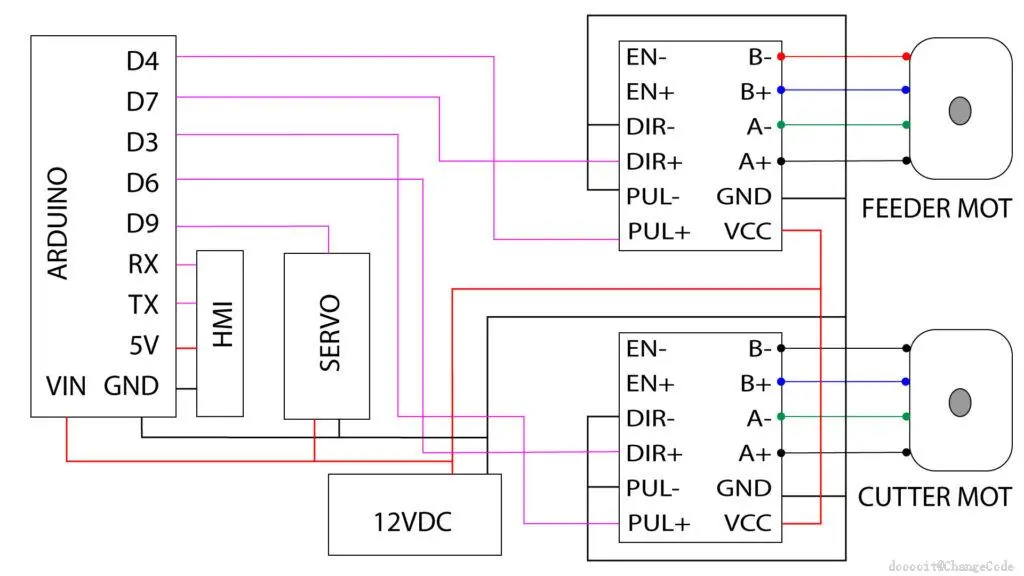

接线图

基于 Arduino 的线切割机接线图

11

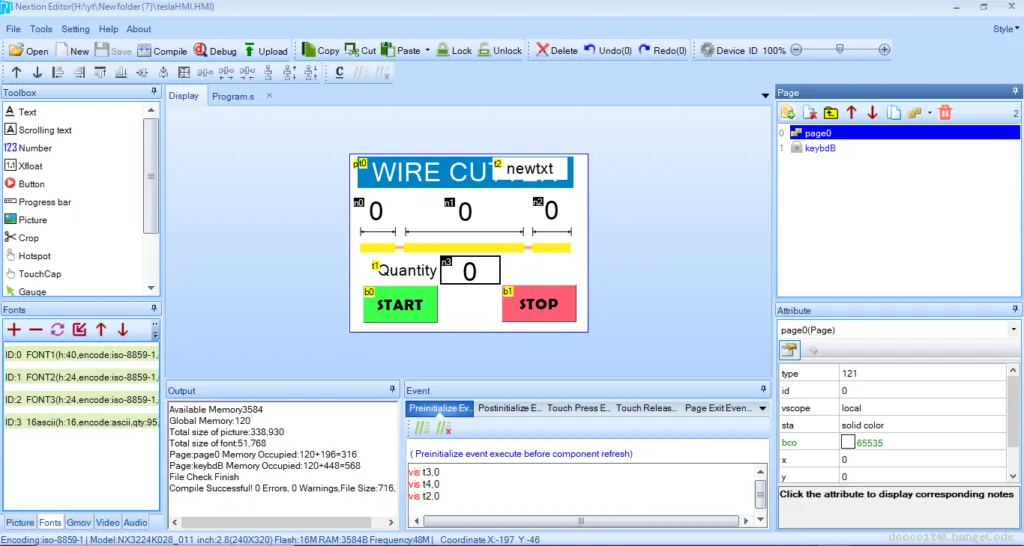

屏幕文件

HMI.tft

699.93KB

12

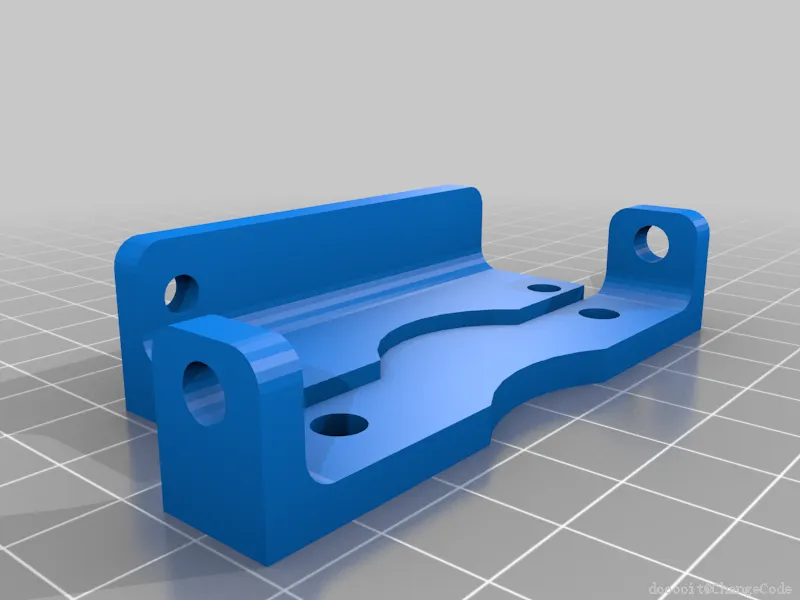

3D 文件

123456

下载3D 文件的链接。

DIY Arduino based wire cutting machine - 5599845.zip

1.83MB

0

0 0

0 0

0 qq空间

qq空间  微博

微博  复制链接

复制链接  分享

分享 更多相关项目

猜你喜欢

评论/提问(已发布 0 条)